416-268-4493

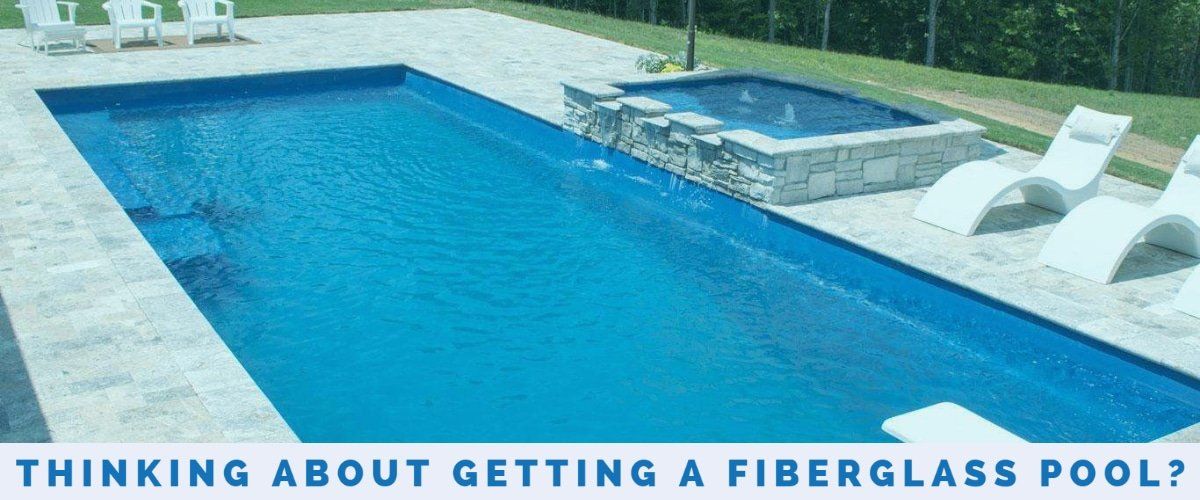

What You Need to Know About Fiberglass Pool Gelcoat Surface Costs

Gelcoat isn’t exactly the word you would think to describe the surface of a pool. In fact, the word gel itself doesn’t really instill any sense of structural integrity if you get my drift. So, it begs the question, what is gelcoat. Really?

Let’s begin with the gelcoat surface.

We sourced our information from top fiberglass pool manufacture River Pools and Spas, even though every manufacture does it differently and uses different types of gelcoats it’s a good starter.

What you really need to know about fiberglass pool gelcoats:

- What they actually are

- How they are applied

- How they get tested

- How they compare overall to a concrete pools plaster finish

- How they compare to a vinyl liner pools

- What makes them different

What is a gelcoat?

A gelcoat is basically a coloured resin. It creates the inside part of the surface layer of a fiberglass pool. It’s a liquid too, so it’s easily stored in drums until it’s sprayed on to the surface of the pool with compressed air. If you happen to be looking at the pool shell of a fiberglass pool, the gelcoat is your pool colour.

How are gelcoats applied?

The gelcoat is applied with compressed air through a spray gun. Compressed air is the backbone of the gelcoat application and having the air clean and dry is of upmost importance. For that reason, it takes several steps of purification before it actually meets the resin.

The gelcoat should be applied in 3 separate passes ending in a total thickness of 25-30 mils. I know this doesn’t seem like much, but the range is super critical! If it’s too thin, it could get blisters due to an improper cure and if it’s too thick, it could crack.

A little cool fact is the pool shell isn’t the only place where the gelcoat is used. The mold itself also has a gelcoat finish.

How are gelcoats tested?

A piece of the fiberglass pool shell is put on top of boiling water and the steam reacts with the gelcoat surface. It isn’t exactly submerged in the water.When the test piece of shell is removed from the water, the difference can instantly be seen between the regular gelcoat and the circle that has been made from the steaming pot.

Why bother doing this?

The expedited reaction actually reveals how the surface will perform under stress over the course of time. It also shows how much the colour fades and if osmotic blisters form. It’s a test that reveals so much with just a small piece instead of waiting to see the effects on an already installed pool.

The Difference Between Concrete Plaster Surface and Fiberglass Pool Gelcoat

The three main components to test here are:

- Texture

- Appearance

- Maintenance

Texture

The plaster surface of a concrete pool can get so rough that it can actually draw blood. Yes, you read that right. This is tough for adults, but can you imagine how worse it is for small kids?

The gelcoat of a fiberglass pool however is quite smooth to the touch. The textured surfaces (like steps), which you might think would be tough on the feet, aren’t rough at all, just anti-slip.

Appearance

You don’t have to worry much with either choice here. Regular wear and tear aren’t going to damage a gelcoat or plaster pool surface.

Maintenance

A plaster’s porosity pretty much invites algae. So much so that you need to steel brush it weekly and acid wash it every 3-5 years just to keep up maintenance. On top of that, you need to replaster the pool and replace the waterline tile every 10- 15 years. Who wants to do that?

A gelcoat on the other hand is much less porous, so the algae doesn’t really bother it. Honestly, with proper manufacturing and maintenance, it’ll never need to be refinished.

Difference Between Fiberglass pool gelcoat and vinyl liner pool surface

Much like the last comparison, there are three main components to distinguish the differences between the two:

- Texture

- Durability

- Maintenance

Texture

There is virtually no difference here as both a vinyl liner and a fiberglass pool gelcoat are both smooth to the touch, other than the ridge where one piece meets the other.

Durability

A vinyl liner needs to be replaced every 5-9 years and it can easily be punctured or torn before it even gets that far. For instance, dogs shouldn’t walk on the steps or even the tanning ledges because something as small as their claws can poke holes in it.

Whereas a fiberglass pool gelcoat, if manufactured correctly and maintained properly will never need to be refinished. It’s actually so strong that things like dog claws, stray tree branches and other day to day wear won’t damage it.

Maintenance

Yes, a vinyl liner is smooth and relatively algae-resistant, but algae can still pop up in seams and corners where water just doesn’t circulate.

The gelcoat surface on the other hand is smooth and 100 percent algae resistant which means that algae literally has nowhere to grow.

How a Top Fiberglass Pool Manufacture Explains the Gelcoat Process:

When it comes to gelcoat surface pools, it takes more than just the installation to get it right. There is a process of chemistry done called polymerization which is where individual molecules cross-link with one another to form chains. The more the molecules bond together, the stronger the final product ends up being.

Catalyst concentration

So, it all begins as the gelcoat catalyst initiates the cure. If there’s too much then the gelcoat cures too fast. If too little, then it won’t achieve a full cure at all.

The concentration of the catalyst needs to be 1-2%. This also depends on the environmental conditions.

The catalyst concentration is usually set before the spraying of each pool to make sure the gelcoat will get to its optimum cure and end up standing the test of time.

The perfect temperature

Temperature is nothing to mess with here. It’s critical. You want to have the temperature at 77 degrees when spraying the gelcoat and other resins.

You know you have a great manufacturer when the facility where they make the gelcoat material and mold has a controlled temperature that stays within optimum range.

Air system

One of the worst things for resin and gelcoat are moisture. If water is introduced at any point in the construction of your fiberglass pool then you’re preventing a full cure.

That means that the resin or gelcoat finish may not be as durable as it should.

Because the products are applied by air, they are only going to be as good as the air in which they are applied with. That means that if there is water in the air compressor then there is water in the pool shell and that’s not okay at all.

There is nothing wrong with asking what kind of air compressor your manufacturer uses. If they have a state-of-the-art air compressor that powers their spray guns, then they’re doing it right. It doesn’t hurt to have an air dryer and multiple water separators to remove the water and other contaminates of the air.

So that way, the process ends up being that the air comes out of the compressor, then through a separator to the pull the moisture out of the air, then through the dryer to dry it again and then through yet another separator to dry it again before the air reaches a spray gun.

I’d say that is definitely locking down the process.

No mold blemishes

Pretty much, if you apply gelcoat on a mold that has blemishes, then the pool is going to have blemishes. A bad mold will always produce a bad pool shell. There are no exceptions to that rule.

This is why the manufacturer should make sure that each mold is blemish free before building a pool on top of it.

There you have it, what you need to know about fiberglass pools and their gelcoat surface finish.

OUR RELATED SWIMMING POOL TOPICS

Pool & landscape products specifications are believed to be accurate at the time of original publication.

Viewers should verify specifications & installation requirements with the installing dealer or manufacture’s manual rather than relying on information on this website, which is not intended to be a final specification.